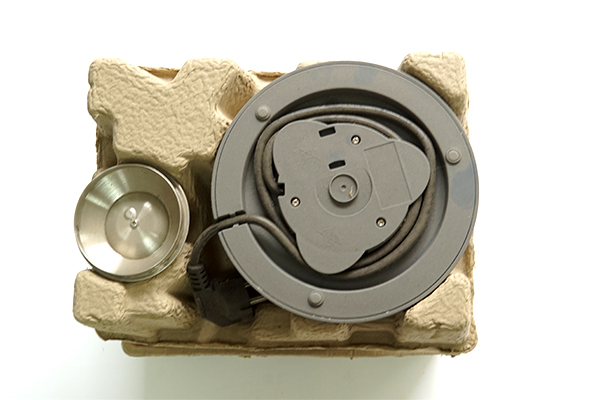

At present, paper trays are a new type of packaging favored by many industries. Therefore, many paper tray manufacturers have emerged in China. The production process of paper trays includes vacuum forming and grouting. The following Baihua Paper Products The staff will tell you about the forming process of paper tray products!

1. Vacuum suction molding method: It is the most popular method for paper-plastic products. According to its different structure, there are three ways: drum type, flip type, and reciprocating lifting type.

Rotary drum type: continuous rotating production, high production efficiency, large investment in mold shells, high mold processing accuracy, high technical requirements for equipment processing accuracy, one set of concave molds with eight sets of convex molds. Need to use the CNC center to process the mold, the processing cycle is long, and the investment is large. Because it is continuous production, it is suitable for mass production of stereotyped products, such as trays, dinner trays, and egg trays. For industrial molding production, it is not applicable due to non-standard, small quantity, small batch, and large investment in molds.

Flip type: lower production efficiency than drum type, suitable for medium batch and non-standard production of industrial molding, but because it is a set of concave molds with two sets of punches, the mold needs to be processed by a CNC center, and the mold shell investment is large and the cycle time is large. long. Reciprocating lift type: The production efficiency is the same as the flip type, which is a common production method at present. Because the equipment only needs a set of concave molds to match the convex molds, and does not need CNC center processing, it is especially suitable for non-standard, small batch, and fast cycle industrial packaging products. (Industrial packaging product mold production cycle is usually within 10 days)

2. Grouting method: According to different pulp packaging products, the injection molding method calculates the required amount of slurry (material) and quantitatively injects it into the molding cavity for adsorption molding. This kind of forming method adapts little to changes. The finalized standard products are commonly used in tableware forming products. Since the finalizing calculation is difficult to grasp, this forming method is not used in non-standard paper-plastic packaging (industrial packaging).

The above are the commonly used processes in the production of environmentally friendly paper trays, which can create high-quality paper tray products. Heshan Baihua Paper Products focuses on the environmental protection paper support industry, welcome customers to contact us!

Address: Pinghan Village Committee Industrial Development

Zone, Gonghe Town, Heshan City

Phone:0750- 8307312

Mobile:18138060289(Mr. Li) 13266450566(Mr. Lin)

Email:1315998615@qq.com

Follow WeChat |

public account |